Microprocessor

- tecqusition

- Mar 4, 2022

- 3 min read

WHAT IS A MICROPROCESSOR?

A microprocessor is a computer processor where the data processing logic and control is included on a single integrated circuit or a small number of integrated circuits.

MANUFACTURING OF MICROPROCESSOR

The world is producing data at an unprecedented rate faster than our ability to analyze and understand it to move store and compute all this data requires incredible processing power from the blazing speeds of our devices to blazing trails within AI. They build chips that are the heart of nearly everything within every intel manufacturing facility across. The globe innovators are pushing the limits of science and rearranging atoms to create groundbreaking technology to strong silicon foundation is what gives each chip limitless potential at the heart of all modern electronics. The transistor is a tiny switch 10,000 times smaller than a human hair that controls the flow of electrons through a circuit to build a processor. Billions of transistors are packed into an area no larger than a fingernail. It’s one of mankind’s most complex feats and a remarkable achievement that the manufacturers have essentially doubled transistor density in every new generation of processors.

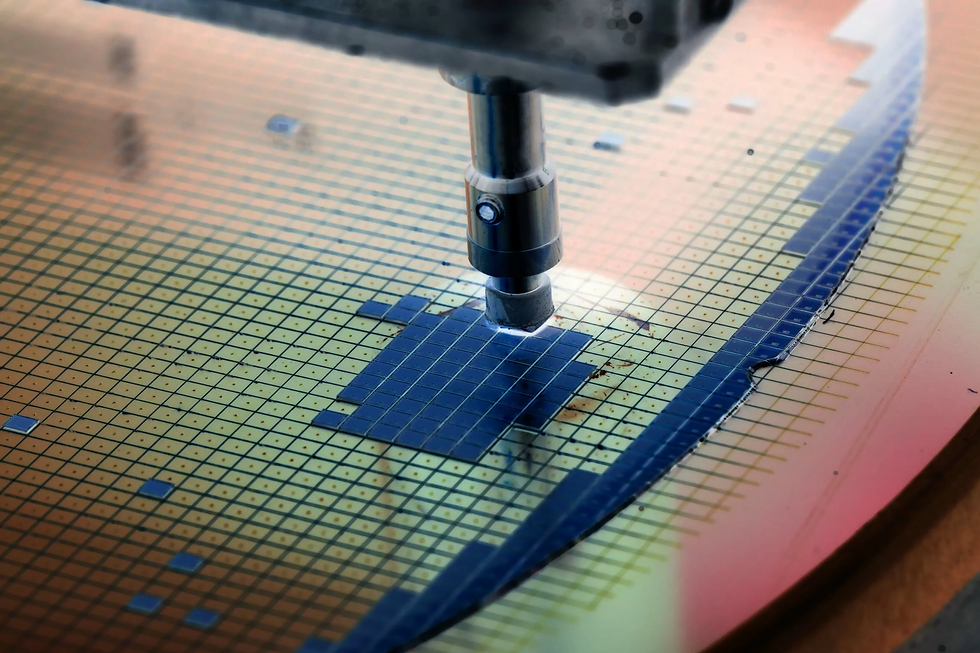

The process begins when silicon-rich sand is melted and cooled forming a solid which is then sliced into wafers. Once inside a fab, the raw wafers begin their long journey through an incredibly complex proves they’re loaded into front opening unified pods or founds that travel hundreds of miles along the automated superhighway going from tool to tool. As processors are painstakingly built upon each wafer the wafer first goes through a series of important steps such as photolithography ion implantation and etching that prepare it for the critical transistor formation process. Intel was the first to manufacture three-dimensional transistors called FinFETs. FinFET construction requires first building a channel in the form of a fitting. Intel has devised several innovations to overcome fundamental barriers to continued transistor scaling one such innovation is a breakthrough fabrication method called gate last. It involves building than removing a temporary gate to precise place the dielectric material and metal gate. This allows for the gate to wrap around the fin and control the flow of electrons through the channel. Another invention moves the transistor contact directly over the active gate to accomplish this the gate material is recessed and then filled with an insulating dielectric material to prevent the creation of a short circuit. Next, the dielectric near the gate is etched filled with metal recessed and capped to allow a novel self-aligning process that enables the high-density contact geometries. Now the dielectrics are etched selectively to expose only the desired part to connect to the first metal lines this is done through an innovative edge and deposition scheme allowing contact over an active gate to happen. Finally dozens of layers of metal interconnect lines are added to complete the circuit. After more than a thousand of these complex steps, the wafers are finally prepared for singularly and packaging. Innovative processor packaging has become a critical feature of advanced computing architecture.

2D and 3D packaging technologies are enabling new device form factors and additional boosts in performance and energy efficiency testing of the final product ensures that every chip exceeds our performance and quality standards in addition to adding more performance and features with each new processor generation integrated design and manufacturing capabilities have enabled humanity to innovate game-changing technologies that impact nearly every fact of modern life. Intel keeps power in the world at the same time we’re powered by you the makers the dreamers the people who shared the history of making the world smarter faster and more connected.

FOLLOW US ON INSTAGRAM, FACEBOOK AND PINTEREST

DISCLAIMER

The information is provided by Tecquisition for general informational and educational purposes only and is not a substitute for professional legal advice. If you have any feedback, comments, requests for technical support or other inquiries, please mail us at tecqusition@gmail.com.

Comments